Tefaş A.Ş. is an automotive Supplier company, started on their actions in 1983 at Topkapı location.

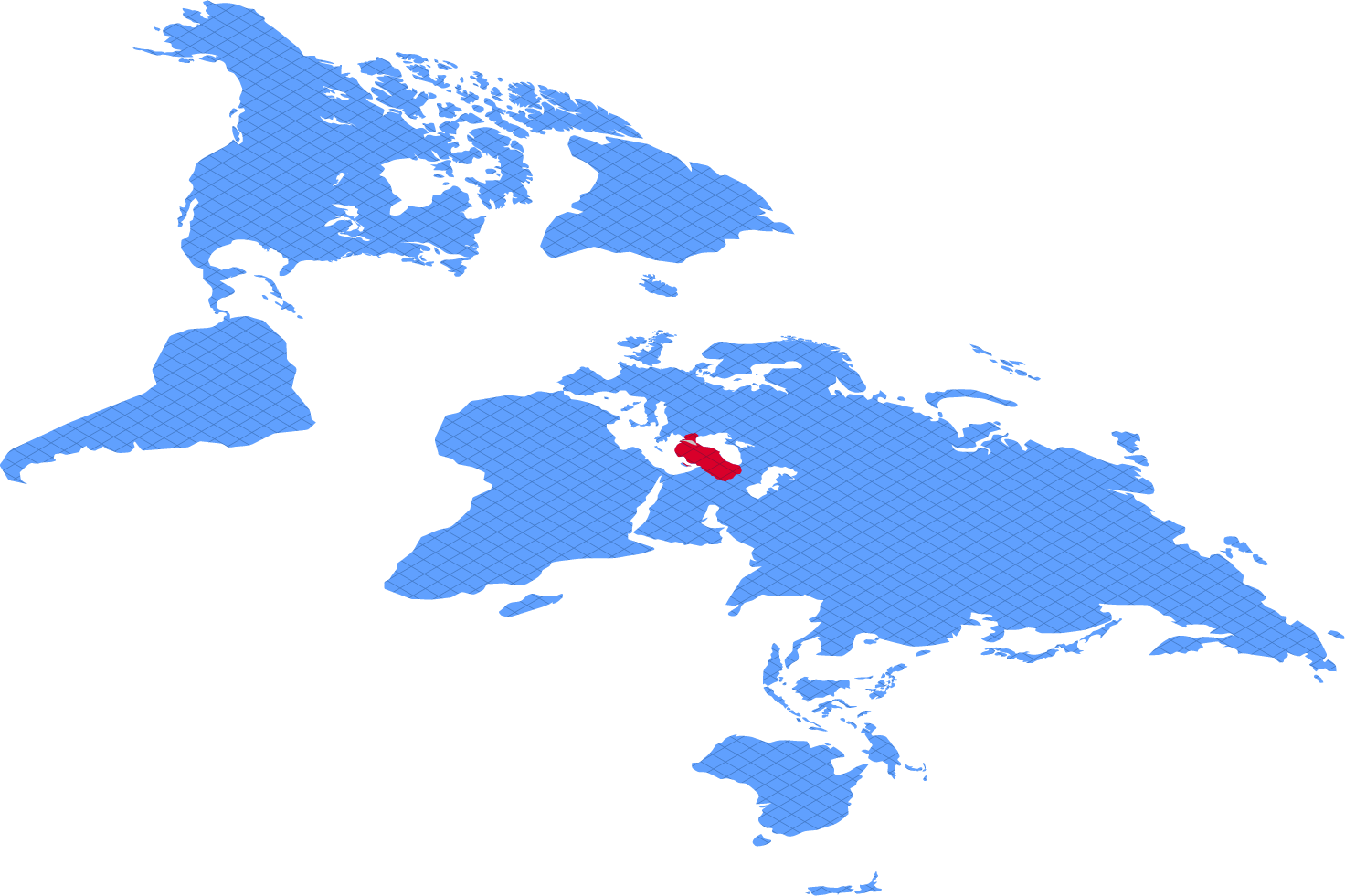

Currently, our company serves the leading OEMs of the automotive sector from 2 locations, Topkapı and Gebze, with a total of 26000 m2 closed area. It adapts to the requirements of industry and continuously improves its production techniques. With our high know-how and experience, we aim to increase human safety Tier-1 companies (Co-Designer) with high strength and lighter designs.

Offer high-quality lightweight products with reliability to meet the needs of our customers.

Until year 2030, our aim is to become Turkey’s leader in automobile parts manufacturer in terms of capacity and productivity.

Total of 60 press lines from 50 Tons to 1600 Tons including Progressive, Transfer and G2 Robotic Line.

Spot welding machines with 120 – 320 kVa power and integrated current control unit. Cold Welding / Aluminium / CMT Product assembly is carried out with the help of Poka-Yoke in the spot, projection, Mig / Mag welding robot cells.

Thanks to our automatic lines that can make powder coating and electrostatic (ZnFe, ZnNi, Fe) coating, surface treatment operation can be performed in-house.

Tefaş R&D department continue his actions to compile its knowledge gained through Projects developed jointly with the main automobile industries in cold forming, welding and multi-coated parts’ for designing and manufacturing them.

Tefaş Company started their production with cold stamping products for one of the leader automobile industry Renault.

Inhouse Zinc (Zn) and powder painting coating lines added to our competencies.

Ford joins our customer portfolio.

Second facility built in Dudullu / Istanbul area.

ISO 14001/16949 certificated.

Dacia company was added to our customer portfolio.

Dudullu facility moved to new and high production capacity plant Gebze at the location Taysad/Gebze with 20000m² covered area.

Certified by Renault Lab.

1000 Ton G2 Press Line integrated.

SAP ERP Software integrated.

1600 Ton Transfer Press Line integrated.

Spot welding lines added to our competencies.

Ford – Otosan joins our customer portfolio.

First company in the industry to use CMM device.

First company in the industry to apply arc welding.

Hyundai company was added to our customer portfolio.

Robotic ZiNi coating line added to our competencies.

Robotic arc welding and spot welding added to our competencies.

Certified by Ford Q1.

1200 Ton Tranfer Press Line integrated.

Certified by VDA 6.3

Tefaş A.Ş. nin yeni koltuk üreticisi partneri Teknik Malzeme firması..

Devamını Göster

2021 yılı yerli ve yabancı pazardaki otomobil soğuk şekillendirme parçalarının ihtiyacının karşılanması

Devamını Göster

German manufacturer MAN is among our customers!

Devamını GösterGümüşsuyu Caddesi No:12 34010 Topkapı / İstanbul - Türkiye

TOSB TAYSAD Organize Sanayi Bölgesi 3. CADDE NO: 19 Şekerpınar Çayırova / Kocaeli- Türkiye